Metals ERP solution

Achieve sustainable growth with a tailored Microsoft™ technology solution.

Achieve sustainable growth with a tailored Microsoft™ technology solution.

Are these problems slowing your metals company down?

Crowe Metals Accelerator, built on the Microsoft Dynamics 365™ platform, is designed to meet the unique needs of metals companies.

Standardize more efficient business processes and increase productivity across multiple metal product types, metal manufacturing processes, and different end customer needs.

Get accurate data and real-time analytics from your metals enterprise resource planning (ERP) solution. Use these analytics to maximize margins, minimize machine downtime, and increase customer satisfaction.

Gain access to the latest innovations from both Microsoft and Crowe rolled out in automatic updates.

Take advantage of built-in Microsoft Azure™ artificial intelligence and machine learning to forecast customer demand and avoid costly machine downtime.

Manage your manufacturing processes for better cost tracking and product performance analysis.

Provide end-to-end visibility to inventory dimensions such as OD/ID, pipe schedule, tube gauge shape, and length to allow for faster order fulfillment.

From coil, sheet, plate, and long product processing to complex fabrication and assembly, easily manage the unique combination of process and discrete manufacturing in a single, end-to-end ERP solution.

Get the tool set to help improve customer service, increase inventory visibility, and more effectively plan operations.

Optimize material planning, integrate production control, and improve quality management.

Communicate in real time to manage inventory, production specifications, quality, shipping, and receiving.

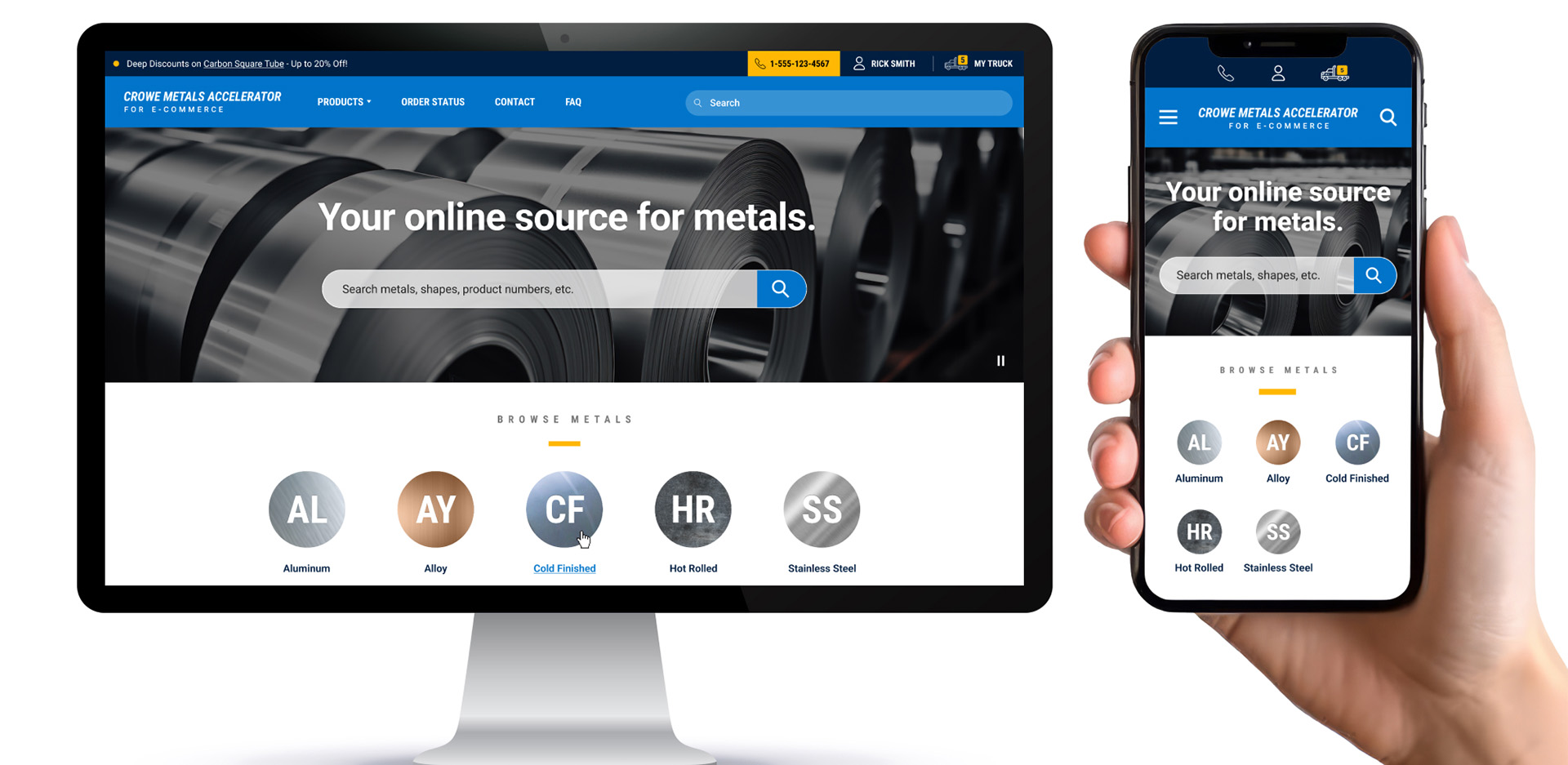

E-commerce

Inventory management

Nesting solution

E-commerce

E-commerce

Built on the Dynamics 365 platform, Crowe Metals Accelerator for E-commerce is a pre-built template that enables metals companies of all sizes to easily create and manage a business-to-business (B2B) e-commerce website for their customers to find, research, and order metal products.

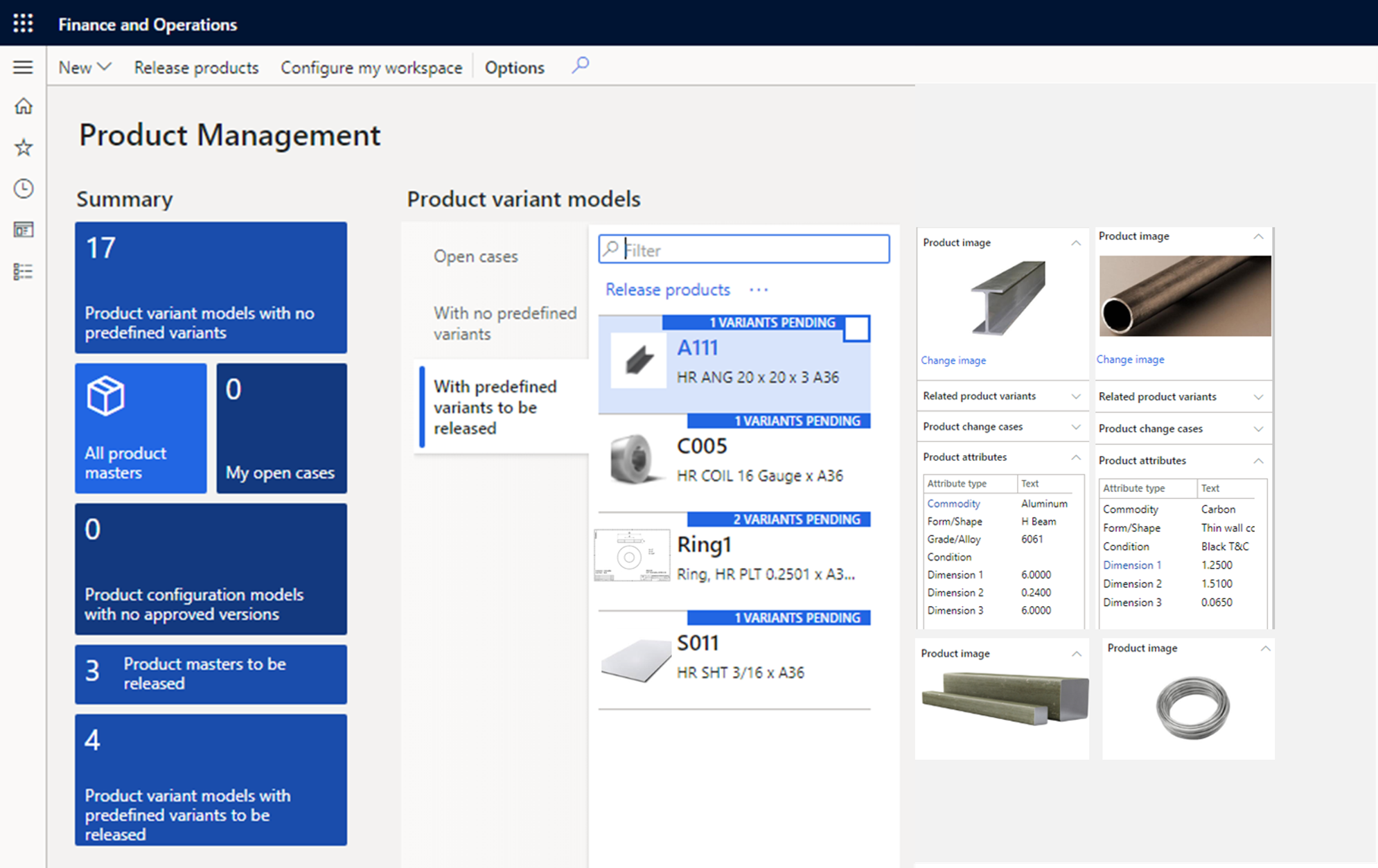

Inventory management

Inventory management

Optimize inventory across multiple locations no matter the form, including coil, bar, plate, pipe, tube, billet, ingot, wire, cable, and fabricated parts.

Nesting solution

Nesting solution

Provide competitive quotes, deliver them quickly, and achieve potential savings on material costs with both linear and plate nesting integrated into quoting and planning.

Customer-defined order specifications are linked directly to manufacturing processes.

Characteristics such as grade, thickness, and diameter are tracked, viewed, and shared seamlessly across all shapes, including coil, sheet, plate, bar, pipe, tube, wire, slab, and billet.

Integrated quality checks – from purchased material receipt through production reporting – provide visibility for quality control.

Flexible conversions allow items to be purchased, stocked, sold, produced, and priced in different units of measurement.

Inventory is optimized through cut- and slit-planning and melt makeup workbenches, including a prebuilt integration with SigmaNEST® software.

Heat traceability is maintained throughout the supply chain, including inventory and production processing.

Weight variances and random lengths are handled with ease.

Inventory can be searched by attribute, and promise dates can be calculated and based on material availability and processing times to help deliver faster customer service.

Flexible price models allow pricing by attribute or weight brackets, cost-plus pricing, and commodity price management.

Mill test reports can be automatically imported from vendors to generate product certifications for customers.

Complete the form to let our team know you’re interested in a 30-minute demo. We’re ready to schedule a call, show you how it works, and answer any questions you might have.

Microsoft, Dynamics 365, and Azure are trademarks of the Microsoft group of companies.