- Americas

- Asia Pacific

- Europe

- Middle East and Africa

How To Manage Supply Chain Volatility: The Case For Airship Freight

The coronavirus crisis has been especially disruptive to the logistics industry, exposing how vulnerable it is to shocks that ricochet across complex and global supply chains. Lockdowns and border closures have led to shortages of critical goods, longer shipment lead times and other delays.

As a result, for many businesses it meant being unable to either predict or guarantee deliveries. Leaders now realize how crucial it is to strengthen the resilience of their supply chains, as well as focus on sustainability. Today, things that would have been considered fringe ideas in the recent past are now being seriously considered – including airship freight.

Crowe Global’s Art of Smart is designed to enable leaders to make smarter decisions and is founded upon four pillars: boldness, diversity, innovation, and growth. As the world rethinks supply-chain transportation, what growth opportunities and innovative use cases does a long-forgotten transportation system offer?

Some industry leaders view the airship – which can be traced back to 1670 when Francesco Lana de Terzi, sometimes referred to as the ‘Father of Aeronautics’ published a description of an “aerial ship” – as a viable solution, but not everyone is convinced.

Rapid growth in ecommerce and just-in-time distribution have increased port, road, and airport congestion. Geopolitical issues, including the Brexit fallout, have further complicated supply chains.

To top it all off, the grounding in March 2021 of the 400-meter, 224,000 gross tonnage container ship Ever Given in the Suez Canal highlighted an overreliance on critical maritime chokeholds, as identified by Chatham House. The canal accounts for 12 percent of the world's sea freight and the blockage held up approximately US$ 9.6 billion in trade.

Currently, freight movement requires a multimodal network – ships, trucks, trains, and air transport – to deliver raw materials, components, and finished goods. As concerns over global warming grow, business leaders must address the environmental hazards of these networks and build sustainability into their supply-chain pipelines.

Airship freight may answer many of these challenges, but there are many hurdles to overcome.

Can airships achieve lift off?

Barry Prentice, Professor of Supply Chain Management at the University of Manitoba, Canada and the President of Buoyant Aircraft Systems International says: “Three factors have lined up to push high growth in the airships industry – sustainability, technology, and new markets.”

In the race to net-zero emissions, transportation, and especially air travel, are among the biggest obstacles. While airplane fuel efficiency improves slowly, the growing demand for air travel and freight has outpaced advancements.The International Civil Aviation Organization forecasts that emissions will triple by 2050 because of growing demand for flights. Mr Prentics estimates environmentally damaging sectors will be taxed, and carbon offsetting,seen by many as greenwashing, will become more expensive. With new emissions standards and a reversal on fossil fuel subsidies, the cost of operating planes will rise.

The industry sees this as the elevator pitch for airships.Gennadiy Verba, CEO ofAtlas LTA Advanced Technologies, an Israeli airship manufacturer, says: “For the same payload capacity, cargo airplanes burn 65 percent more fuel in flight compared to the Atlant 30, on a per tonne-km basis.” This doesn’t include the fuel cargo planes burn during take-off and landing, which can be as much as 30 percent more, according to Atlas’ estimation.

Atlas LTA’s Atlant 30 and the larger Atlant 100 will haul cargo up to 18 and 60 tonnes, similar to the Boeing 737-400F and Boeing 767 F, respectively. Verba expects both to take flight in three to five years. A third airship, the Atlant 300, is currently in a conceptual stage. It is being designed with 165-tonne capacity in mind – a 30 percent increase compared to its closest aircraft competitor, the Antonov 124.

The new generation of airships are a hybrid between lighter-than-air (LTA) airships and heavier-than-air (HTA) aircrafts. LTAs get their name because they use the buoyancy of gases, such as helium and hydrogen, to achieve lift. Consequently, LTAs were slow and highly susceptible to weather patterns. Instead, the hybrids combine buoyant lift of LTAs with HTA technology, such as aerodynamic wings and fuel engines, to improve speed and reliability.

All-electric flight is the final step in decarbonization of aviation. Low fuel consumption makes airships the perfect vehicle to introduce such flight, through technologies such as liquid hydrogen fuel cells.

Finding the sweet spot: fast and cheap

Present-day logistics has a large, unaddressed gap. Prentice explains: “Currently, transportation is divided between fast, but expensive air freights and cheap, but slow surface consignment – ships, trucks, and rail.” There is a sweet spot there for faster-than-ground, but cheaper-than-flying, which airships fill.

Prentice’s research shows that for distances over 1,000km, airships become competitive with trucks on a per tonne-km basis, while reducing overall travel time. This could disrupt distribution of perishable goods over long distances that sees tremendous supply chain waste. For example, a study in India showed anearly 30–40 percent loss of total perishable food production. In-transit damage, dockside storage times, and poor transport infrastructure were major causes. Airships can reduce food spoiling, because of faster last-mile delivery and near-zero vibration that decreases damage to fruits and vegetables.

COVID-19 has highlighted the complexities of multimodal last-mile logistics. For smooth functioning, supply chains must be supported with tremendous ground infrastructure. Even a small delay at one leg of the process can have bullwhip repercussions through the entire system.

Trucks and trains require roads and railways and planes and ships need ports. In the past, airships needed to be supported with large hangars and mooring masts. Breakthroughs in airship design have changed that. Verba explains: “The Atlant uses vertical thrust and adaptive mooring. It can take off and land cargo on flat surfaces not much larger than the airship itself." With airships capable of delivering inland and overseas, single mode last-mile delivery is finally on the horizon. Businesses and governments are boldly exploring the new opportunities this brings.

Single mode last-mile delivery on the horizon

In Kenai, Alaska, Straightline Aviation is establishing a hybrid airship hub to support the activities of coal, copper, silver, zinc and gold mines being developed there. Straightline will operate 12 of Lockheed Martin's new hybrid airships. They hope these airships will be in service in two years. Mark Dorey, Chief Operating Officer of Straightline Aviation, a UK airship operator, says: "With little to no transport infrastructure, we can access the inhospitable Canadian tundra, the Brazilian forests, parts of Central Africa, and the Australian outback."

Roads and railways needed to connect these regions are often not economically viable because of the low population and shipment density. And even when they are, building the infrastructure does calamitous damage to the ecology of the region. Airships can help overcome this disconnect, making new trade routes and sources of raw materials viable.

Prentice gives the example of Flying Whale, a French airship manufacturer. Working with the Office national des forêts (French National Forestry Office), Flying Whale is developing airships for the logging sector. Their intended purpose is to collect logs while hovering. If successful, the logging industry will have access to a much wider area of operation without needing to build roads to support their trucks.

Money matters

According to Prentice, the major challenge has always been financing. Airship manufacturing has a high barrier to entry. He says: "You're no good until you get big. And the bigger the airship, the bigger the infrastructure, and hangars you need to build it." A lack of government support has made it impossible for airships to become a viable contender so far.” As an economist, I'm yet to see any transportation system – railways, roadways, air, and shipping ports – develop without strong government support. This has not happened yet for airships, but things are slowly changing.”

He offers Flying Whales, which has received funding from governments in France, Canada and China, as an example again. "It is the first commercial application of air shipping to receive government backing in 85 years."

Airship historian and consultant Dan Grossman cautions: "There's the romance of airships and then there is the reality. There are serious players and others that rely on press releases with computer-generated images.”

With many of the technologies yet to be proven beyond tests, it is difficult to separate the hype from fact. Among the hybrid manufacturers, Grossman advises choosing partners with good past experience getting aerostats, the traditional LTA airships, off the ground.

Big backers: close to a tipping point?

Despite these challenges, there is growing enthusiasm for the sector. Over the past four years, Sergey Brin, co-founder of Google, has invested in LTA Research and Exploration. The company aims to build airships powerful enough to travel across oceans and provide humanitarian aid and disaster relief.For vast swaths of the world, adequate access to transportation infrastructure doesn’t exist. People living in these remote regions can’t easily access goods, trade, fresh water, and health care. From putting out forest fires, bringing in emergency supplies to disaster zones, to bringing in water to drought stricken areas, airships open up new opportunities for humanitarian aid.

Straightline Aviation has partnered with RAD-AID, a health care non profit, to propose a medical airship service. The vibration-free airships can move sensitive medical equipment. Straightline plans to offer free radiology services to remote regions that lack proper health care access.

Prentice is optimistic about airship freight, and adds: “Historically, every major transportation innovation since the industrial revolution has spiked economic growth."

The airship's return has been a long time in the making. Most industry experts Art of Smart spoke with anticipate initial hybrid airships being fully operational by 2025.

For bold decision-makers seeking to grow their market and diversify their supply lines, plus drive towards a sustainable and profitable future, the time to start planning is now – before the sector takes off, finally.

Comparison

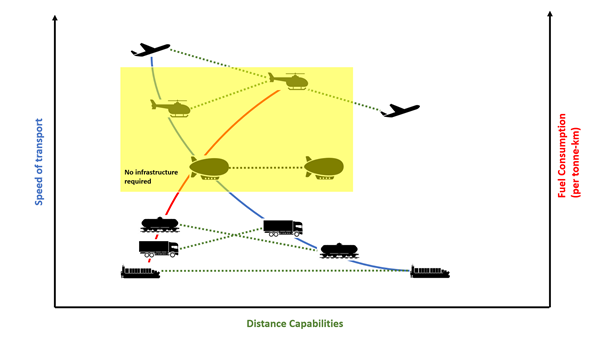

The chart represents the speed, distance capabilities, and fuel consumption of various modes of freight transport. It is based on estimations from Straightline Aviation and Atlas LTA.

Understanding The Possibilities of Airship Freight

How airships improve the supply chain, in theory:

- Access to remote locations

- Point-to-point delivery of oversized cargo

- Long-range flight with minimal infrastructure

- Operate in harsh weather conditions

- Very low emission;, soon to be net zero

Business leaders thinking on about bringing airships into their operations must ask themselves these questions:

- Does it help you access remote markets that were previously inaccessible to your goods or services?

- Can you find raw materials and energy sources in parts of the world that traditional transport can't reach?

- Can it open your business to new trade routes or complement existing ones?

- Can they back up your existing means of transport if natural disasters or pandemic-induced lockdowns block parts of your supply chain?